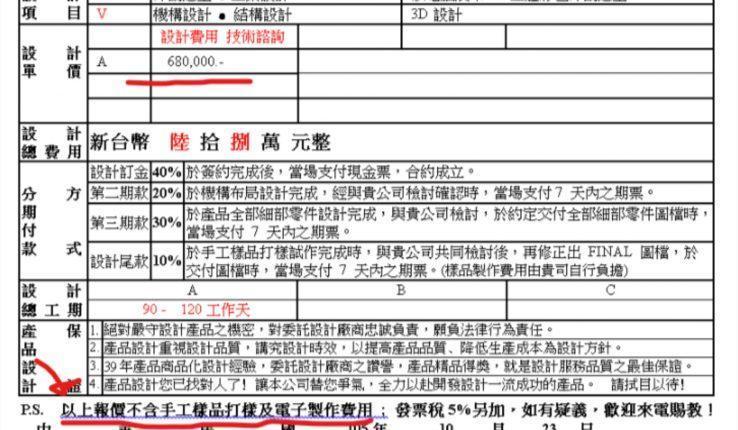

Although the concept is simple, when I tried to carry out this plan, I ran into endless challenges and frustrations. My previous training as a firmware engineer only covered the technical knowledge of the electric parts, not including the mechanical design. Therefore, at the beginning of the Muro Box project, I had no idea of how to design any workable mechanical structure.

I was dreaming like many engineering guys who tried to invent something great. I thought once I finished the software coding, someone will magically show up later to help me fix the rest of mechanical problems and then the final product can be made soon. This kind of illusion stayed for several months, until my brother came to my home to wake me up with harsh comments and suggestions. This was a reality check I needed. After realizing the fact, I must put aside my coding work and search for professionals to help me solve the mechanical design problem.