We are facing a dilemma with the damper issue. While we want to increase the shock absorption strength, the damper itself can also create noise. Conversely, to reduce the noise generated by the damper, the shock absorption strength becomes insufficient.

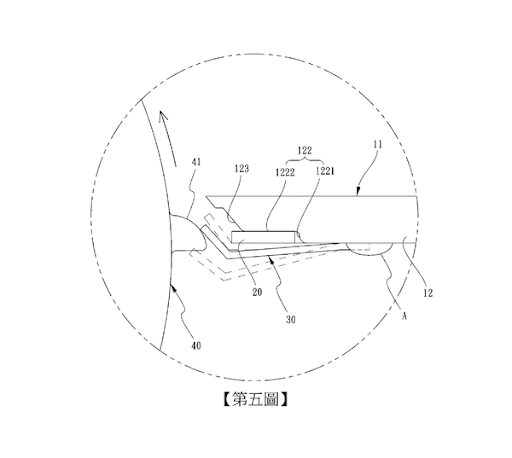

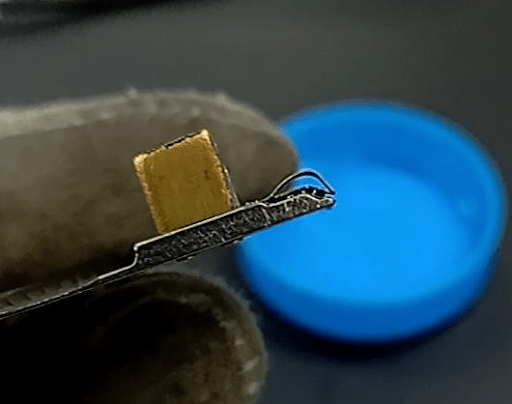

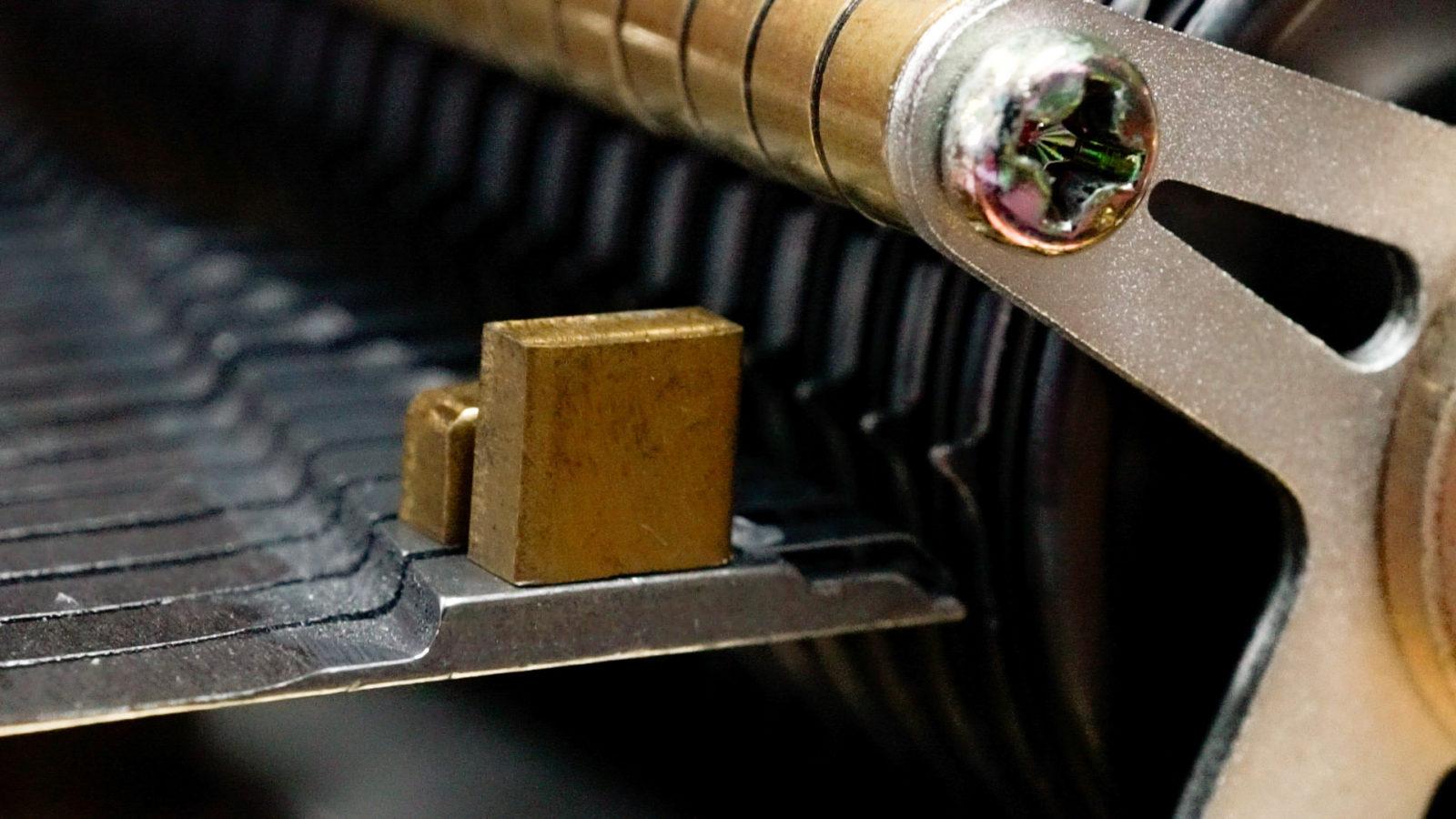

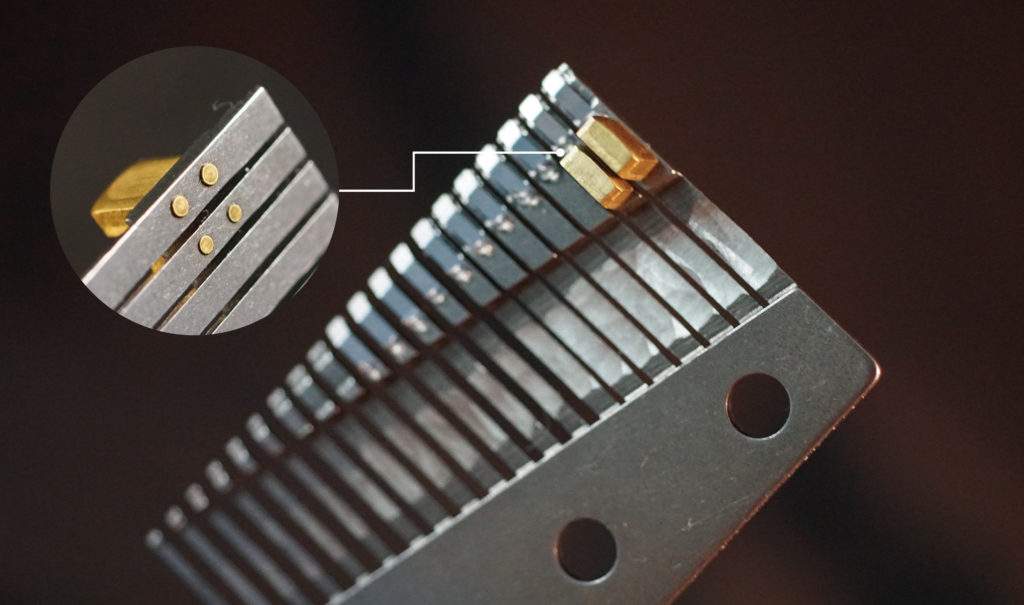

Our design uses a metal spring as a buffer for the contact between the comb and the striking flexible pins, where the size of the “shock absorption capability” depends on the size of the front opening. A larger opening allows the spring to deform more, absorbing more impact force. However, if the opening is too large, it becomes challenging to control the relative position of the spring and the front end of the comb, which can lead to noise.

In simple terms, if the damper protrudes too much, it will extend the comb too far, resulting in louder sound. This problem is relatively mild, as it only sounds louder and does not reach the level of noise. On the other hand, if the position is too shallow, the striking pin will first hit the damper, and then after disengaging, will strike the comb a second time, producing a noticeable abnormal sound that is unacceptable.

All of this occurs within a range of 0.1 mm at the front end of the comb, and we should not underestimate even a small amount of abnormal sound. The human ear is much more sensitive than the eye, and this 0.1 mm distance can definitely be detected.