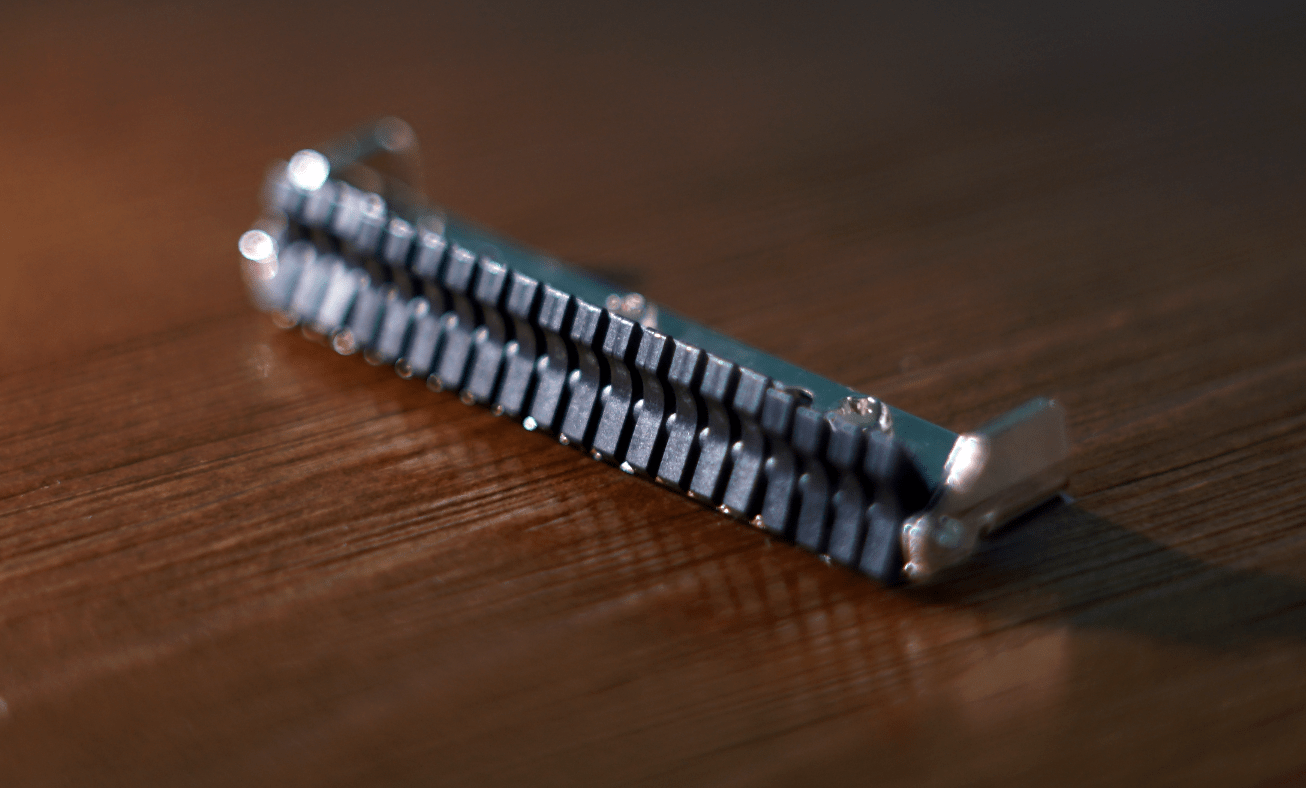

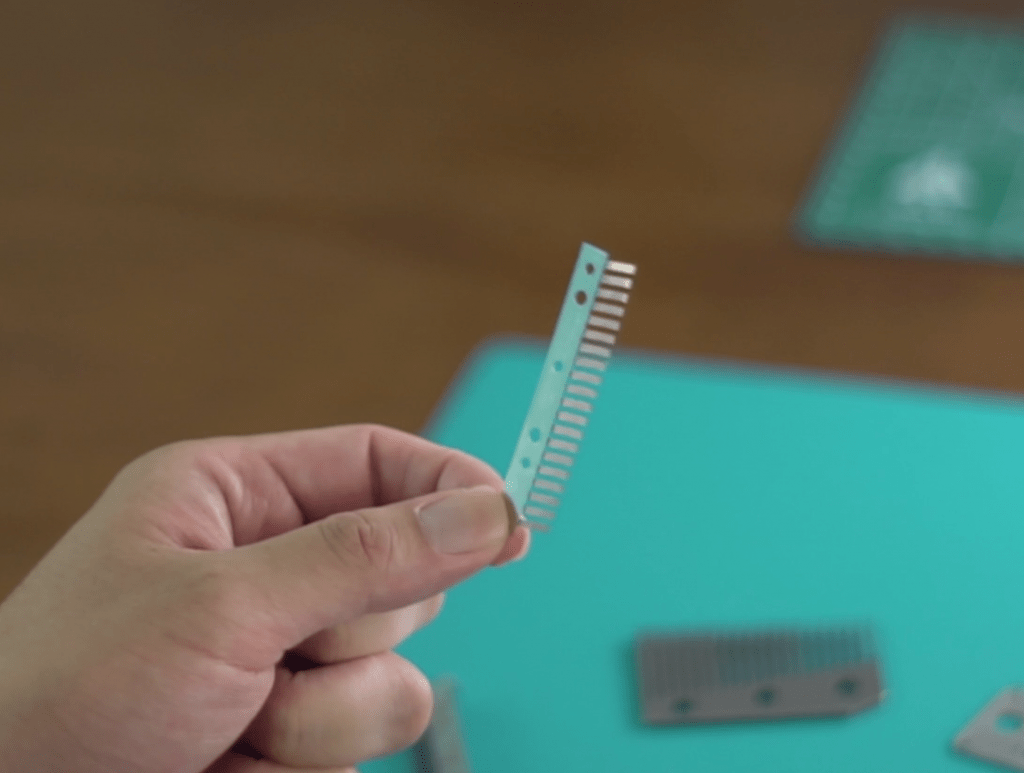

Finding a workable solution is just the first step. We found that the small components of the stopper generate mechanical noise while it operates. Moreover, after the whole Muro Box is assembled, the noise is amplified by the wooden box when Muro Box is playing music. The “crack” sound became an unpleasant noise that interferes with the beautiful melodies played from Muro Box.

We have tested various kinds of acoustic pads and industrial lubricating oil. We also modified the shape of the baffle for pins on the ratchet to hit them from different angles. Our team has invested a lot of effort in reducing the mechanical noise.

Can you imagine that, it requires such a complicated design for just a pin stopper to align the pins at a fixed position after they pluck the comb? Because the sustaining sound is the soul of music box music, we believe all of our effort in research and experiments for the pin stopper will not be wasted. Thanks to this unique device, Muro Box can maintain the sustaining sound effect when playing your favorite melodies.