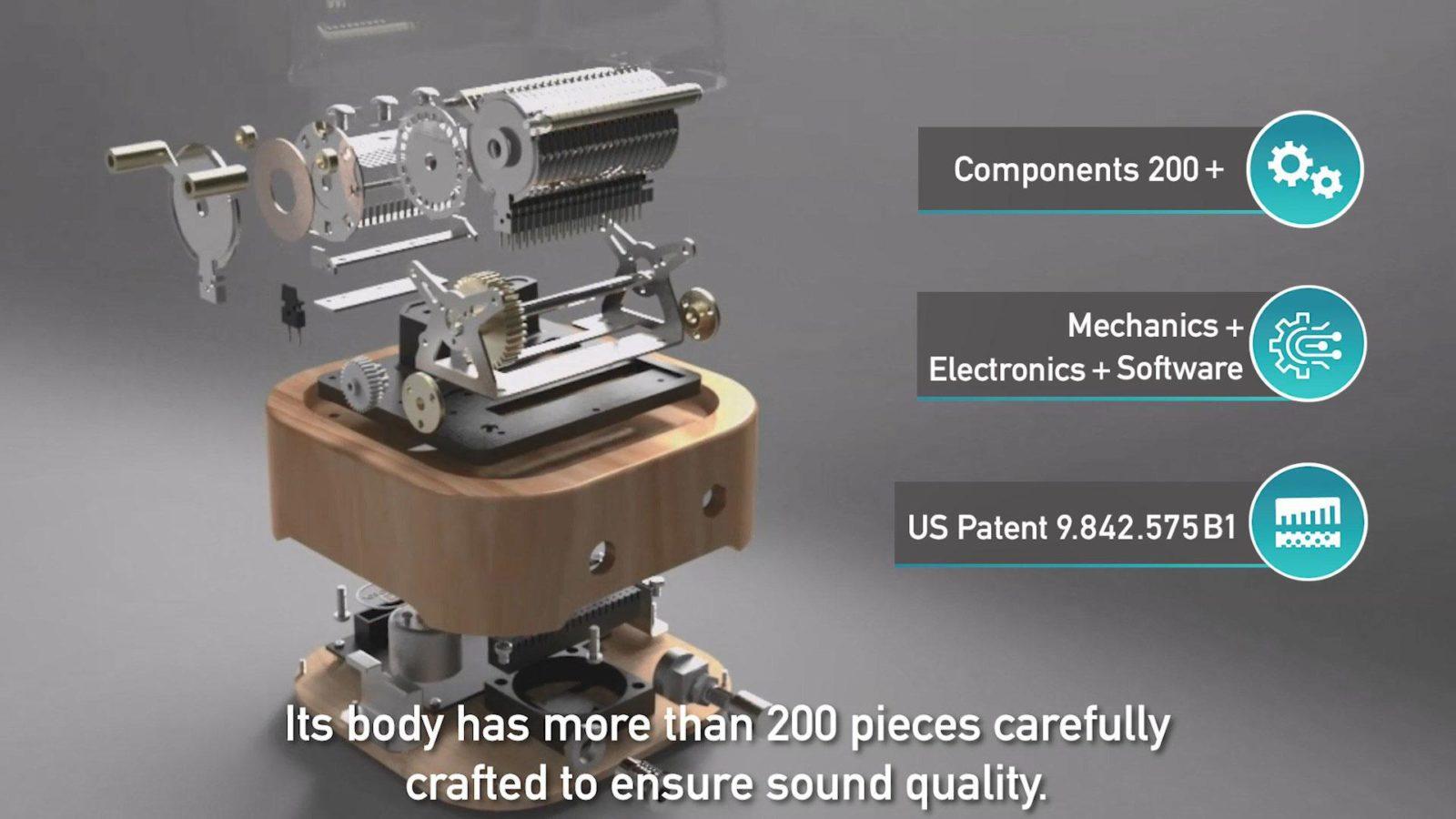

After successfully crowdfunding in our first attempt in Taiwan, we (Dr. Feng and Dr. Tsai, the founders of Muro Box) spent almost 2 years in the pilot run production of Muro Box. The main challenge lies in how to increase its sound quality and durability when producing this mechanical music box. Although we faced endless obstacles, we did not give up our dream to produce Muro Box. We were encouraged by many international customers who expressed their eagerness to own the Muro Box as soon as possible.