Let’s check out the latest N40 Update:

https://murobox.com/……/muro-box-n40-update-17-en/

.

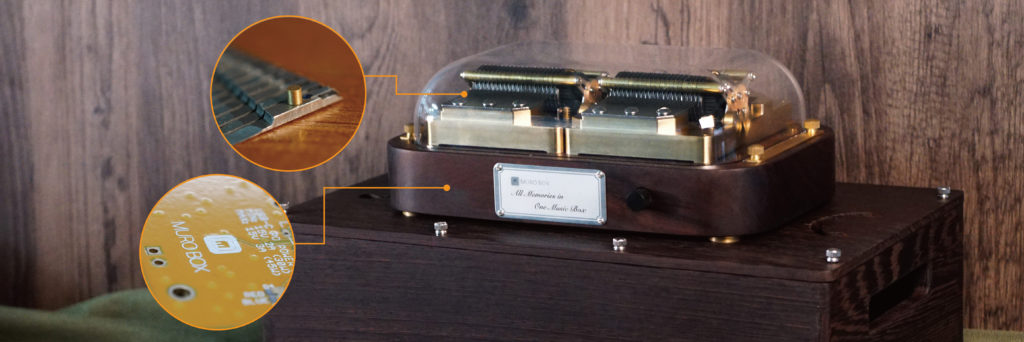

We visited the PCB manufacturer, “Mighty Net” on March 24, 2024, to record the production process of our Muro Box-N40’s PCB.

.

In this N40 update, you will see the following highlights:

(1)The Production Process of N40’s PCB in the video:

The production team uses visual analysis on the computer to verify each tiny component on the PCB is correctly installed/printed.

.

(2)Do you know why we selected the yellow color for the premium model of Muro Box N40? See the details in this update.

.

(3)In order to make the comb’s lowest 2 notes have a stable sound effect, we did a series of “turning weight tests”. In the end, we decided to use an innovative production method that has not been used in the music box industry before to drill holes on the comb’s teeth: Electrical Discharge Machining (EDM).

.

Simply put, machines use high-voltage electric currents, and the arc directly vaporizes localized metal on the comb teeth like lightning, causing them to melt at high temperatures. Therefore, there is no issue of overall overheating and annealing of the comb.

Welcome to read our test result and see the current shipping preparation for Muro Box-N40 in the latest update:

https://murobox.com/……/muro-box-n40-update-17-en/

https://murobox.com/……/muro-box-n40-update-17-en/

.

We visited the PCB manufacturer, “Mighty Net” on March 24, 2024, to record the production process of our Muro Box-N40’s PCB.

.

In this N40 update, you will see the following highlights:

(1)The Production Process of N40’s PCB in the video:

The production team uses visual analysis on the computer to verify each tiny component on the PCB is correctly installed/printed.

.

(2)Do you know why we selected the yellow color for the premium model of Muro Box N40? See the details in this update.

.

(3)In order to make the comb’s lowest 2 notes have a stable sound effect, we did a series of “turning weight tests”. In the end, we decided to use an innovative production method that has not been used in the music box industry before to drill holes on the comb’s teeth: Electrical Discharge Machining (EDM).

.

Simply put, machines use high-voltage electric currents, and the arc directly vaporizes localized metal on the comb teeth like lightning, causing them to melt at high temperatures. Therefore, there is no issue of overall overheating and annealing of the comb.

Welcome to read our test result and see the current shipping preparation for Muro Box-N40 in the latest update:

https://murobox.com/……/muro-box-n40-update-17-en/