N40 Music Box Shipping Slows Down Because the Damper on the Comb Requires Meticulous Craftsmanship

Muro Box-N40 Update #21

Hello everyone,

I’m Dr. Chen-Hsiang Feng, the inventor of Muro Box.

We have identified defects in the dampers of the N40 music box combs that have been shipped. Consequently, we have temporarily halted further deliveries to address this issue. Shipments will resume starting this week. The detailed report is as follows.

Due to feedback from two customers regarding abnormal sounds from the music boxes, we have initiated an emergency response by halting production to investigate the issue.

Upon inspecting the returned units, we identified the defect lies in the damper. The damper did not perform as expected, failing to absorb the impact sound of the previous strike of the same repeated note.

The abnormal sound is related to the melody of the music, becoming noticeable when the same note is repeatedly struck in a short time (4 beats per second).

Here are the questions you might ask, I’ll attempt to answer them here:

1. Is this issue specific to the N40 model? Did N20 have a similar issue ?

The issue was also observed in the N20. Because the main operator who has been stable in production has taken maternity leave. So the new operator caused the issue to happen again. This situation prompted us to gain a deeper understanding of the problem and implement even stricter acceptance standards than before. Consequently, this adjustment has impacted the speed of shipping.

2. I have received N40. Could there be the same issue with my music box, too ?

It’s possible, but as mentioned earlier, this issue specifically arises when the melody involves repeated strikes of the same note in a short time. If you haven’t encountered this issue previously, it may indicate that your machine is not affected, or the problem isn’t immediately apparent. We kindly request that you refrain from initiating maintenance requests immediately, as we are currently short-staffed. Please await our contact before taking any action. The best time for sending maintenance requests will be to wait until we completed the shipping for all campaign backers because at that time all of the possible flaws noticed by other backers will already be solved.

3. Does this issue also exist in traditional mechanical music boxes?

Yes, they do have the same issue. However, the issue is more challenging on the Muro Box for several reasons. First, the Muro Box can strike a single note up to four times per second, which is quite fast for a mechanical music box. It’s difficult to imagine traditional mechanical music boxes playing at such high speed.

Moreover, each note on the Muro Box can be individually programmed, enabling them to be struck at the highest speed. This represents one of the most stringent acceptance methods for music boxes worldwide.

Finally, the Muro Box’s cylinder rotates too quickly (about one circle per second), significantly reducing the effective contact time for the damper. So we need to invent a damper design for the Muro Box that is stronger than any used in music boxes to solve the issue. Developing something from scratch and ensuring it’s more effective than all previous designs is an incredible mission.

4. Can you describe the challenges encountered in the production of damper for the Muro Box?

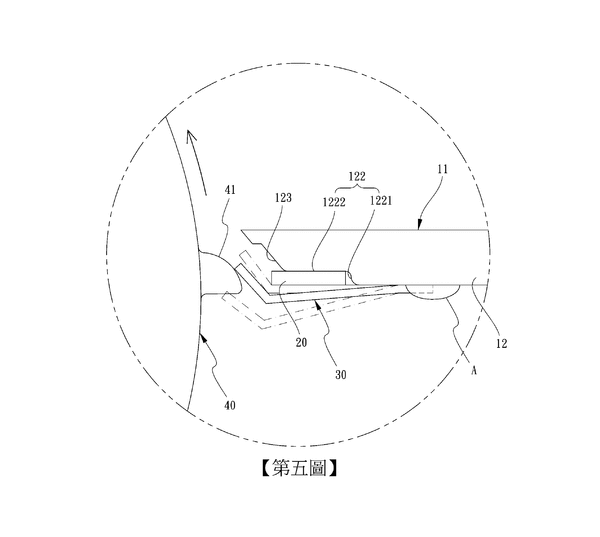

The damper of the Muro Box consists of a vibrating plate, soft pad, and metal clip. Because of manual assembly, the position of the metal clip may vary depending on the operator’s technique.

If the metal clip protrudes too much, it extends the length of the damper, causing specific comb to be struck too high and resulting in uneven volume levels. Conversely, if the metal clip is too short, it may first contact the damper, and leave the damper causing an initial sound. Then contact the comb and leave the comb resulting in a second sound as it disengages, leading to noise.

Therefore, the damper has only one optimal position with very little margin for error. This precise positioning is crucial to avoid issues with uneven volume and noise. That’s why only the most experienced operators are needed for assembling the damper. It takes thousands of times to accurately pinpoint that perfect position.

Making the issue more complex is the fact that the angle of the damper’s front opening affects its damping effectiveness, yet it also influences its position, potentially causing noise or uneven volume. You can imagine why changing the assembling operators can significantly slow down our production rate.

5. Have you found a solution to it ?

Yes. For the long term, the assembly of dampers, which requires experienced operators, itself poses a challenge. So we have initiated a new damper design plan to ensure future models are more effective and easier to manufacture.

As for the current production of N40, we must complete shipping by using the existing mechanism. Hence, we have also improved our production processes based on the current mechanical design.

We have abandoned the method of “placing parts directly into zero-error positions at once” and instead adopted the method of “post-processing parts to achieve zero-error positions.”

In simple terms, we are using post-processing methods to allow more margin for error during assembly by different operators.

We will quickly stabilize the new production methods and catch up with the planned shipping schedule.

We apologize once again for the delay in our shipping process. Despite these challenges, we remain committed and determined. Your patience is greatly appreciated as we work diligently to deliver the finest music boxes to you.

Inventor of Muro Box

Chen-Hsiang Feng