What is Muro Box?

Muro Box is the world’s first and only app-controlled mechanical music box.

Its patented cylinder has flexible pins that break the limitation of the 200 years old music box industry. With Muro Box (music box), now you can enjoy the whole song, not limited to a 15 second segment anymore.

With our free Muro Box App, you can easily find free melodies, compose melodies, and edit your playlists before sending them to play on the Muro Music Box. You can even schedule multiple playlists to start playing music at different times to bring you surprise and joy in daily life.

Let’s create happy memories with your family by creating your own melodies to play on the Muro Box!

Why is Muro Box Your Best Customized Gift Option?

Muro Box can play your most important song on a mechanical music box. Muro Box is like your own musician playing your unique melody to revive your memory in front of you.

Loved by Customers from 50 Countries!

Muro Box is Made in Taiwan

Muro Box has experienced 6 years of product development journey, and gained international customers’ trust from crowdfunding campaigns in Taiwan, the US, Japan and Korea.

Watch Our Global Customers' Music Box Performances

Read Our Global Customers' Stories

The Music Box is the Most Precious Gift from My Father

Emily Gvino

My dad purchased the Muro Box for me as a wedding present for my wedding in June 2019. The Muro Box came ready to play “You’ll Be in My Heart” by Phil Collins, our special song since I was a little girl. He would always play Phil Collins’ CD in the car; my dad, sister, and I would sing along, driving with the windows down in the summertime. We had every word memorized!

Creating My Own Melodies to Play on a Music Box is Not a Dream Anymore

雞湯G.J. Lee

“I am currently devoted to teaching Ukulele. The first time I knew Muro Box was during the 2018 campaign in Taiwan.

I found this company to be admirable. Music box is not a necessity in life, and nowadays many people are not familiar with it. Even though the product may not be profitable, they still did their best to strive for the better sound quality regardless of the high production cost.

Seeing their perseverance in making music boxes into handicrafts and combining the convenience of modern technology to make more people willing to understand music boxes again. Hence, I am touched and willing to spend a long time recording an unbox video to present the fruit of their years of effort.”

Muro Box is the COOLEST MIDI Instrument!

Shawn

“I’ve released a ton of albums and also recorded songs for films and videos. I’m a big fan of the Muro Box – the amazing electro-acoustic mechanical music box that lets you play your own melodies on its tines. You can connect MIDI keyboards, use their app or even send the notes to play from your DAW (like Ableton, etc).”

Now, I can Manage All of My Paper-Strip Music Box Melodies in a Cloud Library!

Hanneke

“When I was around 10 years old I came across a music box that worked with paper strips, and also fell in love with its sound.I spent much of my allowance on preprinted music strips, which I still own – along with that music box.

Many of those songs on paper strips were really well made. It’s those strips that I’m now adding to the Muro Box library.”

Muro Box N40 includes flats and sharps. Let's turn a music box into a music instrument!

Welcome to read our updates about how we designed Muro Box N40.

Our Latest News

We upload the music box playlist based on your request! Let the bespoke music box speak for your heart with customized melodies and create more shared memories!

【Upload the Bespoke Playlist for You!】If you want the gift receiver to watch the music box playing a unique playlist that shows 1~10 songs you picked for him/her when unboxing

Muro Box-N40 Update #15 -Resonance Box Sound Tests on 4 Wood Options; Metal Plate’s Final Design

【Guess which wood gives you the best resonance box sound effect!】Dr. Feng made four resonance boxes with 4 different woods to test their sound effects: -Millettia Laurentii, -Taiwan Acacia, -Japanese

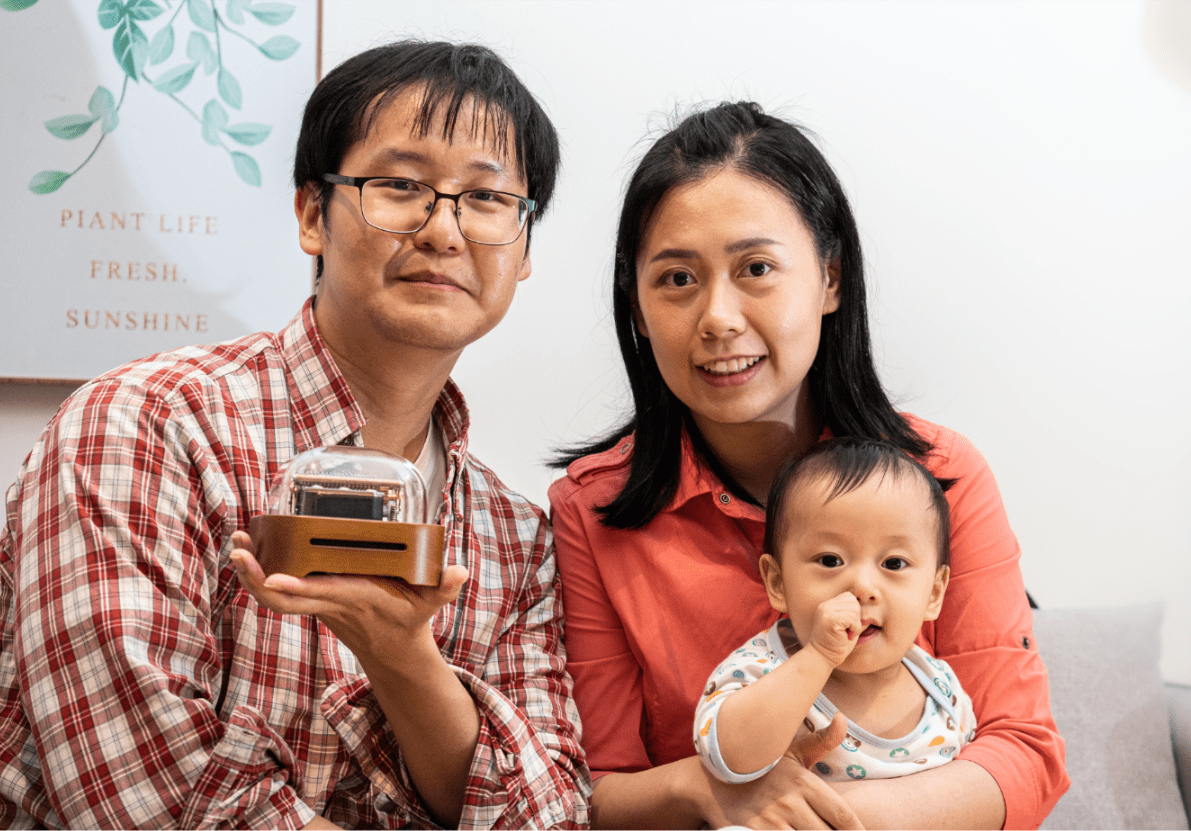

The Origin of Muro Box

After receiving our doctoral degrees in the US, we decided to integrate our expertise in engineering and education to start our own company. A tiny music box we bought in Austria when we first knew each other was the seed that inspired our startup dream.

We haven’t played this meaningful music box for a long time because it repeats the same melody. When listening to its playing, we started to wonder what if the music box can play more songs to present our memories from different stages of life?

While we were recalling our shared memories in the past 10 years, we decided to redesign its cylinder to let it play more melodies of our own choices, and then our product development journey began in 2016.

The Vision of Tevofy Technology Ltd.

“Telling Your Stories with Technology” is our company’s vision. We hope that technology not only brings us convenience in life, but also shortens the distance between people.

Therefore, we invented the music box that can play your own memories. We hope the music box will become each family’s heirloom to preserve their own unique memories.

International Media Reviews

CNET Japan

Muro Box

Read More

Techcrunch

Muro Box

Read More

GadgetMatch

Muro Box

Read More